GOST R 54860-2011 regulates the need for calculations when organizing heat supply communications. Before arranging the line, the owner must determine the necessary parameters of the boiler and batteries. Calculation of heating is also performed to establish the energy efficiency of the equipment and the likely heat loss.

Design parameters

Calculation technology allows you to choose a thermal system suitable for power and length for a house or apartment. The calculation is based on several initial values:

- the area of the building, its height from the ceiling to the floor, internal volume;

- type of object and the presence of other buildings near it;

- materials for the construction of the roof, floor and ceiling;

- the number of window and door openings;

- intended use of parts of the house;

- the duration of the heating season and the average temperature in a given period;

- features of wind rose and geography;

- probable room temperature;

- specifics of places of connection to gas, electric communications and water supply.

Insulation of doors, windows and walls is mandatory.

Room Volume Calculations

The calculation for heating, made by the volume of the living space, is notable for the accuracy of the data. It is advisable to consider it as an example: a house of 80 m2 in the Moscow region with a ceiling height of 3 m, 6 windows and 2 doors that open outward. The algorithm of actions will be as follows:

- Calculation of the total volume of construction. The parameters of each room are summed up or the general principle is used - 80x3 = 240 m3.

- Counting the number of openings facing out - 6 windows + 2 doors = 8.

- Determination of the regional coefficient for the Moscow region, related to the middle zone of the Russian Federation. It will be equal to 1.2. The value for other regions can be found in the table.

| Region | Features of the winter period | Coefficient |

| Krasnodar Territory, Black Sea coast | Warm weather with virtually no cold | 0,7-0,9 |

| Midland and Northwest | Moderate winters | 1,2 |

| Siberia | Severe and frosty winters | 1,5 |

| Yakutia, Chukotka, Far North | Extremely cold climate | 2 |

- Counting for a country cottage. The first obtained value is multiplied by 60: 240x60 = 14,400.

- Multiplication by regional amendment. 14 400x1.2 = 17 280.

- Multiplying the number of windows by 100, doors by 200 and summing the result: 6x100 + 2x200 = 1000.

- Addition of data obtained at stages No. 5 and No. 6: 17 280 + 1000 = 18 280.

The power of the heating system will be 18,280 W excluding materials of load-bearing walls, flooring, and thermal insulation characteristics of the house. In calculations, there is no correction for natural ventilation, so the result will be approximate.

Calculations by the number of floors

Residents of an apartment building pay for utilities, depending on the number of storeys. The higher the house, the cheaper it is to heat. For this reason, the calculation of the heating system is tied to the height of the ceilings:

- no more than 2.5 m - coefficient 1;

- from 3 to 3.5 m - coefficient 1.05;

- from 3.5 to 4.5 - coefficient 1.1;

- from 4.5 - coefficient 2.

You can calculate communications by the formula N = (S * H * 41) / Cwhere:

- N - number of radiator sections;

- S is the area of the house;

- C - the thermal return of one battery is indicated in the passport;

- N - room height;

- 41 watts - heat spent for heating 1 m3 (empirical value).

When calculating, the floor of the residence, the location of the rooms, the presence of the attic and its thermal insulation are also taken into account.

For a room on the ground floor of a three-story building, a coefficient of 0.82 is set.

Selection of a heating boiler

Heating units, depending on the intended purpose, are single-circuit and double-circuit, can be installed wall and floor. Boilers also vary in type of fuel.

Gas modifications

Manufacturers produce various devices, so when choosing you should pay attention to the following factors:

- The purpose of installation of heating communications. Single-circuit options are used for heating, double-circuit with a built-in boiler of 150-180 liters can provide the house with hot water and heat it.

- The number of dual-circuit model heat exchangers. The only bithermic element heats water as a heat carrier and a DHW resource at the same time. In versions with two, the primary heating is used for heating, the secondary - for heating the domestic hot water system.

- Heat exchanger material. Cast iron accumulates heat for a long time and is not subject to corrosion, steel is practically insensitive to temperature fluctuations.

- Type of combustion chamber. The open chamber runs on natural draft, so the boiler needs a separate room with good ventilation. A closed unit removes combustion products through a coaxial horizontal chimney.

- Features of ignition. In the electric ignition mode, the wick will burn constantly, but the equipment needs electricity to operate. Models with piezo ignition are independent, but are turned on manually.

Condensing gas units with a water economizer differ in performance, but the fuel charge is almost doubled.

Electric models

Devices are characterized by almost silent operation, compactness and safe operation. Owners of houses and cottages can purchase modifications:

- On tubular heating elements. Devices with a heating element are suitable for wall mounting, are automated, but often break due to scale.

- On the electrodes. Small devices connected to the circuit of two or more batteries. The boiler is efficient, equipped with temperature settings, but is sensitive to the coolant.

- Induction. Equipped with an overheat protection system, they quickly heat up the coolant, have an efficiency of 97%.

Induction boilers are expensive equipment.

Combined units

They heat any area, can work in universal mode and on two or three types of fuel. Type of power is selected by the user:

- solid fuel + gas;

- solid fuel + electricity;

- gas + electricity;

- gas + diesel.

One type of fuel resources is the main, the second - auxiliary, which does not heat the house, but only maintains normal temperature conditions.

Solid fuel boilers

They work on wood, sawdust, coal, coke, special briquettes, they are safe and easy to use. For a private house, you can choose the units:

- Classic. They operate according to the principle of direct combustion, it is necessary to fill the furnace every 5-6 hours.

- Pyrolysis. They work on the principle of residual gas afterburning in a special chamber. Fuel filling is carried out every 12-14 hours.

Devices require a chimney with good draft, are placed in a separate room. The user must periodically clean the combustion chamber of soot and tar.

Liquid fuel devices

They work on diesel fuel, therefore they are placed in a separate room. The boiler room is equipped with a hood and a high-quality ventilation system. Fuel oil is stored in sealed containers in a separate room. All liquid fuel devices are automated, productive, and feature high power.

- Solid fuel

- Diesel fuel oil

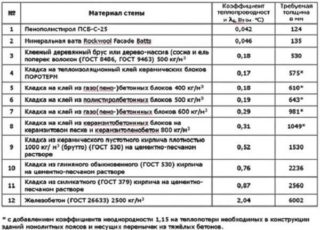

Features of the calculation of heat loss

Most often, the heat depends on the material of the floor and ceiling surfaces, walls, the number of openings, and features of insulation. Autonomous heating can be calculated taking into account heat losses in a private house using the example of a corner room with an area of 18 m2 and 24.3 m3 in volume. It is located on the 1st floor, has ceilings of 2.75 m, as well as 2 external walls of timber 18 cm thick with plasterboard lining and wallpapering. The room has 2 windows with parameters 1.6x1.1 m. The floor is wooden, insulated, with a subfloor.

Calculation of surface area:

- External wall without windows - S1 = (6 + 3) x 2.7 - 2 × 1.1 × 1.6 = 20.78 m2.

- Windows - S2 = 2 × 1.1 × 1.6 = 3.52 m2.

- Sex - S3 = 6 × 3 = 18 m2.

- Ceiling - S4 = 6 × 3 = 18 m2.

Calculation of heat loss of surfaces, Q1:

- External wall - S1 x 62 = 20.78 × 62 = 1289 W.

- Windows - S2 x 135 = 3 × 135 = 405 watts.

- Ceiling - Q4 = S4 x 27 = 18 × 27 = 486 W.

Calculation of total heat loss by summing data. Q5 = Q + Q2 + Q3 + Q4 = 2810 watts.

The total heat loss of one room on a cold day is -2.81 kW, that is, the same amount of heat is supplied additionally.

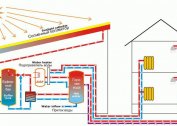

Hydraulic calculation

You can calculate the hydraulics for heating laid in a private house if you know:

- line configuration, type of pipeline and fittings;

- pipe diameter in the main sections;

- pressure parameters in various zones;

- loss of heat carrier pressure;

- The method of hydraulic linking elements of the heating main.

For example, you can use the gravity two-pipe line with the parameters:

- design heat load - 133 kW;

- temperature - tg = 750 degrees, tо = 600 degrees;

- Estimated flow rate - 7.6 cubic meters per hour;

- ways to connect to the boiler - hydraulic horizontal distributor;

- constant temperature maintained by automation throughout the year - 800 degrees;

- the presence of a pressure regulator - at the input of each of the valves;

- type of pipeline - metal-plastic distribution, steel for heat supply.

For the convenience of calculations, you can use several online programs or a special calculator. HERZ C.O. 3.5 considers linear pressure loss method DanfossCO is suitable for systems with natural circulation type. In the calculations, you need to select the parameters for the temperature - degrees Kelvin or Celsius.

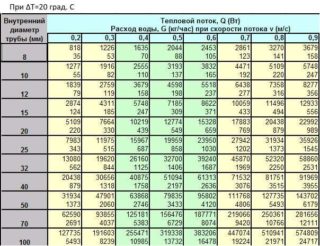

Pipe diameter

The difference between the temperature of the cooled and hot coolant in the two-pipe system is 20 degrees. The area of the room is 18 squares, ceilings 2.7 m high, forced circulation heating circuit. The calculations are made as follows:

- Definition of average data. Power consumption is 1 kW per 30 m3, thermal power reserve is 20%.

- Calculation of the volume of the room. 18 x 2.7 = 48.6 m³.

- Determination of power costs. 48.6 / 30 = 1.62 kW.

- Search for power reserve in cold weather. 1.62x20% = 0.324 kW.

- Calculation of total power. 1.62 + 0.324 = 1.944 kW.

Suitable pipe diameters can be determined from the table.

| Total power | Coolant speed | Pipe diameter |

| 1226 | 0,3 | 8 |

| 1635 | 0,4 | 10 |

| 2044 | 0,5 | 12 |

| 2564 | 0,6 | 15 |

| 2861 | 0,7 | 20 |

Select the value of the total power as close as possible to the result of the calculation.

Pressure Parameters

Total pressure loss is the pressure loss in each section. This value is calculated as the sum of the frictional losses of the moving coolant and local resistance. Counting Algorithm:

- Search for local pressure in the area using the Darcy-Weisbach formula.

- Search for the coefficient of hydraulic friction by the Alshutl formula.

- Using tabular data based on pipe material.

| Outer diameter mm | Friction loss coefficient | The speed of the coolant, kg / h | Local losses, kg / h |

|

Steel pipe |

|||

| 13,5 | 5,095 | 229,04 | 0,0093 |

| 17 | 3,392 | 439,1 | 0,0025 |

| 21,3 | 2,576 | 681,74 | 0,0010 |

|

Electric pipe |

|||

| 57 | 0,563 | 7193,82 | 0,0000094 |

| 76 | 0,379 | 13 552,38 | 0,0000026 |

|

Polyethylene pipe |

|||

| 14 | 2,328 | 276,58 | 0,0063 |

| 16 | 1,853 | 398,27 | 0,0030 |

| 18 | 1,528 | 542,1 | 0,0016 |

| 20 | 1,293 | 708,04 | 0,00097 |

Kilograms per hour can be converted to liters per minute.

Hydraulic linkage

Hydraulic linkage is a necessary step to even out water losses. Calculations are made on the basis of the design load, resistivity and technical parameters of the pipes, local resistance of the sections. You will also need to consider the installation characteristics of the valves.

Algorithm for calculating resistance characteristics technology:

- Calculation of pressure losses per 1 kg / h of coolant. They are measured in ∆P, Pa and are proportional to the square of the flow rate of water in section G, kg / h.

- Using the coefficient of local resistances and summing all parameters.

Information and dynamic pipe pressure can be found in the manufacturer's instructions.

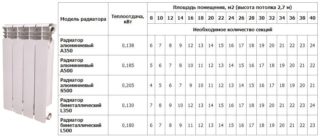

Features of counting the number of radiators

To calculate the number of radiator elements, it is necessary to take into account the volume of the building, its design features, wall material and type of batteries. For example: a panel house with a heat flux of 0.041 kW. It is necessary to calculate the number of batteries for a room 6x4x4.5 m.

Computation Algorithm:

- Determining the volume of a room. 6x4x2.5 = 60 m3.

- Multiplying the area of the room by the heat flux to calculate the optimal amount of heat energy Q. 60 × 0, 041 = 2.46 kW.

- Search for the number of sections N. Divide the result of step No. 2 by the heat flux of one radiator. 2.46 / 0.16 = 15.375 = 16 sections.

- The choice of radiator parameters from the table.

| Material | Power of one section, W | Working pressure, MPa |

| cast iron | 110 | 6-9 |

| aluminum | 175-199 | 10-20 |

| tubular steel | 85 | 6-12 |

| bimetal | 199 | 35 |

The longest service life on the line of cast iron is 10 years.

Calculation of boiler power

Calculation of useful heat for heating each room involves calculating the power of the heating system. Recognizing it, you can create the optimal temperature regime. The boiler power is calculated by the formula W = S x Wud / 10where:

- S - an indicator of the area of the room;

- Wud - specific power parameters per 10 cubic meters of room.

The specific power indicator depends on the region of residence. It can be found on the table:

| Region | Specific Power, W |

| Central | 1,25-1,55 |

| Northern | 1,54-2,1 |

| South | 0,75-0,94 |

An example of calculating the thermal power of a boiler connected to a heating system for a room of 100 squares in the Central region will be: 100x1.25 / 10 = 12 kW.

An approximate calculation is often used: a boiler with a capacity of 10 kW will heat 100 m2.

How to choose heating appliances

In external design, heating appliances are similar, but during the selection, design features must be taken into account.

Convection devices

Heaters quickly generate heat through air circulation. At the bottom of the convectors are openings for air intake, inside the housing there is a heating element, heating flows. Convection equipment is:

- Gas - connects to the main line of the house or cylinder. Units are energy efficient, but their installation must be coordinated with regulatory authorities.

- Water - connects in the bottom or side way, quickly heats up. Devices are not suitable for rooms with high ceilings.

- Electric - connected to the network, have an efficiency of up to 95%, low noise. The downside is the high energy consumption.

1 kW / h of energy is spent on heating 10 m2 of area using convectors.

Radiator systems

They are connected to heating lines in the lower, lateral or universal way. Made of the following materials:

- Aluminum - light, quickly heat up, heat resistant. The threaded connection of the upper intake valve is of poor quality.

- Bimetal - equipped with a steel core and aluminum body. Withstand high pressure, but are expensive.

- Cast iron - characterized by high heat capacity and long cooling.The disadvantages of the devices include slow heating and heavy weight.

Aluminum batteries do not withstand pressure fluctuations and are not suitable for apartments.

Convective Radiator Installations

They are realized by connecting a water heated floor and radiators, and are used in country houses in server regions. Effective in heating corner or glazed rooms. Under the windows, you can install sectional (4-16 cells) or panel (solid body) batteries. The warm floors on the first floor are covered with ceramic tiles, on the second - with any material.

- Non-convection batteries

- Convection radiator batteries

Rules for installing heaters

Regulatory installation requirements are prescribed in several SNiPs and include:

- Safety monitoring of the temperature of radiators - no more than 70 degrees.

- Removing batteries 10 cm from the side of the wall, 6 cm from the floor, 5 cm from the bottom of the wall, 2.5 cm from the plaster.

- The presence of a nominal heat flux is 60 W less than the calculated one.

- Making connections within the same room.

- Existence of automatic adjusting fittings in premises and manual adjustment in bathrooms, bathrooms, dressing rooms, storerooms.

- Compliance with the slope of the eyeliner by the movement of the coolant by 5-10 mm.

- Threaded connection of aluminum and copper devices.

- Constant filling of the system with coolant.

The documents also noted the need for routine inspection and cleaning of devices from dust before the start of the heating period and once every 3-4 months during operation.

Thermal calculation for heating communications is carried out individually. Energy efficiency, safety and ease of use of the system depend on the accuracy and accuracy of the calculations.